Gas-lighted Street Lamps in Olden Times

View of Orchard Road from the junction of Grange Road c 1905

The antique-designed street lamp in Orchard Road was lighted with gas by City Council workers.

My blogger friend Lao Kokok posted his "Times Of My Life" well-researched [Kampong Bugis or "火城"] blog here

to learn more. Thus I add-on a similar blog topic as a supplement to other stuff to share.

|

| Courtesy of Dr Tan Wee Kiat of ReTRIeVIA .

In 1993, a street-lighting ceremony was held at Clarke Quay to revive the memories of pioneer generation Singaporeans who remember that lamps in the public streets were lighted with gas by the City Council workers when night falls.

The brightly lit and decorated streets of Orchard Road are nowadays electronically and automatically switched on with timers during the Christmas lighting up and other festival events.

Thanks to the resources from newspaperSG of the National Library Board's online eResource. Archived photos on this blog for credit to the National Archives of Singapore.

OUR GAS INDUSTRY

Another Municipal Activity.

EFFICIENCY AND ECONOMY

(Source: The Singapore Free Press and Mercantile Advertiser (1884-1942), 26 October 1926.

It is now over 40 years since gas was first introduced to the public of Singapore and anybody who seeks a little knowledge of things connected with the local gas service cannot fail to be struck, not only by the tremendous advance that has been made since gas was first used here but also by the work that is done at the Municipal plant at Kallang, where millions of cubic feet of gas are now manufactured in a year.

In its early stage of introduction here its use was almost entirely restricted to lighting. Our roads were brightened up and the residents welcomed the many advantages that gas lighting and, later, cooking, offered them. Since those days there has been a gradual expansion in the use of gas particularly with regard to industrial purposes and use in the home for cooking and water heating. The annual production of gas is now 300,000,000 cubic feet against 165,000,000 cubic feet per annum ten years ago.

Everyone knows that gas is manufactured from coal, coke and oil, and at the Works at Kallang all the processes can be seen in operation. In order to take round a visitor and explain the different stages of gas production, a whole morning would be required, but the visit would prove very interesting. One gazes in fascination at the huge retorts and the blazing furnaces below and passes from the sweltering heat of these compartments to spotlessly clean rooms where the pressure governing apparatus and the controlling meter are installed.

Location of the former Kallang Gas Works in olden times Singapore.

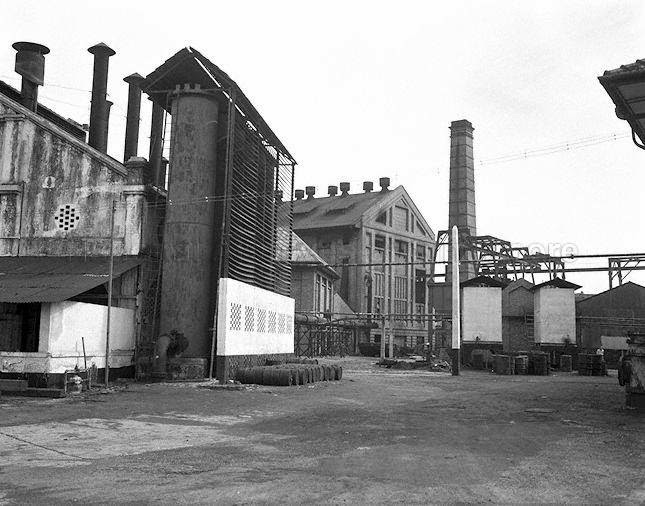

The Kallang Gas Works c 1910

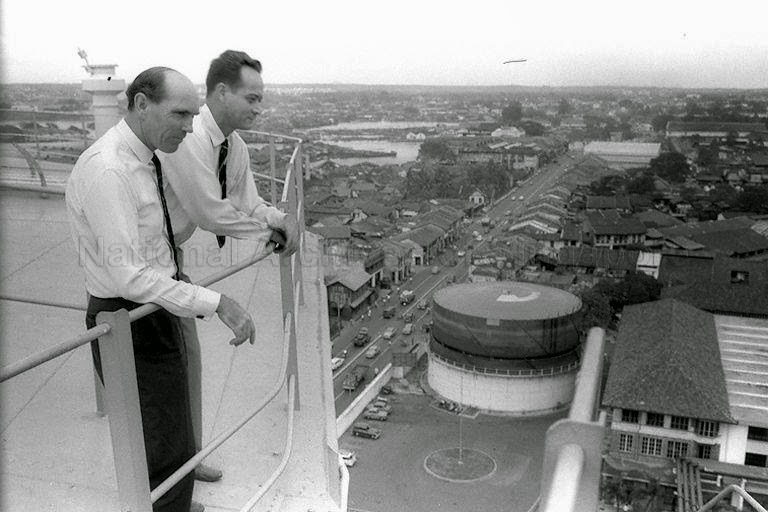

Visitors to the former Kallang Gas Works

Minister for Law E W Barker (right) visited Kallang Gas Works on 11 November, 1964

Each process requires careful control as it is now the practice to send out a strictly uniform quality of gas to meet the requirements and adjustments of the apparatus in use in the town.

Surrounding the retorts and furnaces are huge stacks of coal. Usually about 6,000 tons of coal is kept in stock as reserve. It is Australian coal and is brought up the Kallang river to the rear of the works in the coal thus stored from becoming over-heated, so the temperature is checked weekly and when it is found that the coal is becoming too hot it is dug out and carbonised.

The coal is mechanically conveyed to the retorts by an endless chain of buckets and deposited into overhead hoppers leading into the retorts which ate externally heated to a temperature of 1250 deg. C.

The By-products

Here the gas and volatile products of carbonisation are driven out of the coal, collected and purified. The gas being freed from tar, sulphuer and ammonia, is finally pumped into the gas holders for distribution into the mains. The holders at Kallang and the large one at Kreta Ayer, by reasons of their respective situations, ensure that there is no weakness of distribution to any part of the town.

About 20 per cent of the gas manufactured is made from coke and oil. In this process coke in a large generator is raised to a white heat by means of turbo-blowers and then steam is blown through the incandescent mass, thus producing a high grade cas, by heating value of which can be varied by the introduction of volatilised oil. The process is mechanically controlled so that when the coke becomes cooler by the introduction of steam, the steam is cut off and the coke again blown to a high heat. Some 300,000 cubic feet of gas is manufactured here daily.

Storing the Gas

The storage of the prepared gas presents difficulties which are not generally appreciated. The gas is pumped into the gas holders which are telescopic and sealed in large tanks under water, the pressure of gas to the town being produced by the actual weight of the holder floating in the tank. At the outlet of each holder an automatic governor is in operation whereby a constant pressure is maintained.

A queer little machine looking quite out of place next to the big pumping engines, separates the clinkers from the coke which comes out from the furnaces in an unburnt form, and saves about 40 tons of coke a month.

During the process of carbonisation of coal very little of the energy of the coal is lost and it is this efficiency and also the production of valuable bye-products which enables gas, particularly as a source of heating, to be most economical.

The coke from the gas retorts is of a soft free-burning type and is particularly in demand for forge and glass furnace work. The tar produced is distilled and a good dehydrated tar for road purposes and painting is produced while an excellent wood preservative is also prepared during the distillation

Gas-cooking Popular

There is no longer any doubt that the public of Singapore have learnt to appreciate the economy and other advantages of gas cooking. This is proved by the demand for gas-cookers on hire during the last year. Particular attention has been paid to the cleansing of cookers before they are dissembled as the works where there is a special department to deal with them. The parts are immersed in a bath of boiling caustic soda so that they are rendered entirely free from any possible infection. Apart from the allurement of a hygenic and clean kitchen and the spick and span appearance given by gas fixtures and fittings, the comfort of a hot bath has resulted in a demand for geysers quite unknown here some two or three years ago.

It is of interest to know that the gas department is quite a self-contained body having its own workshops which are quite a hive of industry. Thus, in walking round, one is surprised amongst other things to come upon say the construction of lamp posts, which are being made of reinforced concrete and will probably be capable of baffling those motorists who are constantly trying conclusions with street lamp posts. Very little of what goes on inside the works can be gleaned from an outside view, and there is nothing prepossessing about the place beyond the two large holders and a 90 foot brick chimney but an inside inspection is very full of interest.

|

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home